With a potential COVID-19 exposure I decided to work outside in order keep my housemates’ exposure as low as possible. This afforded me the perfect opportunity to test running a high performance laptop from my batery bank and on solar power. I wanted to bench test integrating a West Mountain Radio Epic PWRGate into the existing battery box that had been intentionally designed without and integrated charger. The first and second days of the test with good and poor sunlight respectively went well. The solar panels were holding the battery up and by the time I was done working the battery was fully charged. It is worth noting that earlier in the morning the laptop was running on the battery, but as the sun came up the battery began recharging in both cases. Of course the battery charged more slowly and sometimes went into a discharging state on the cloudy day but ultiately all the power drawn from the battery was replentished.

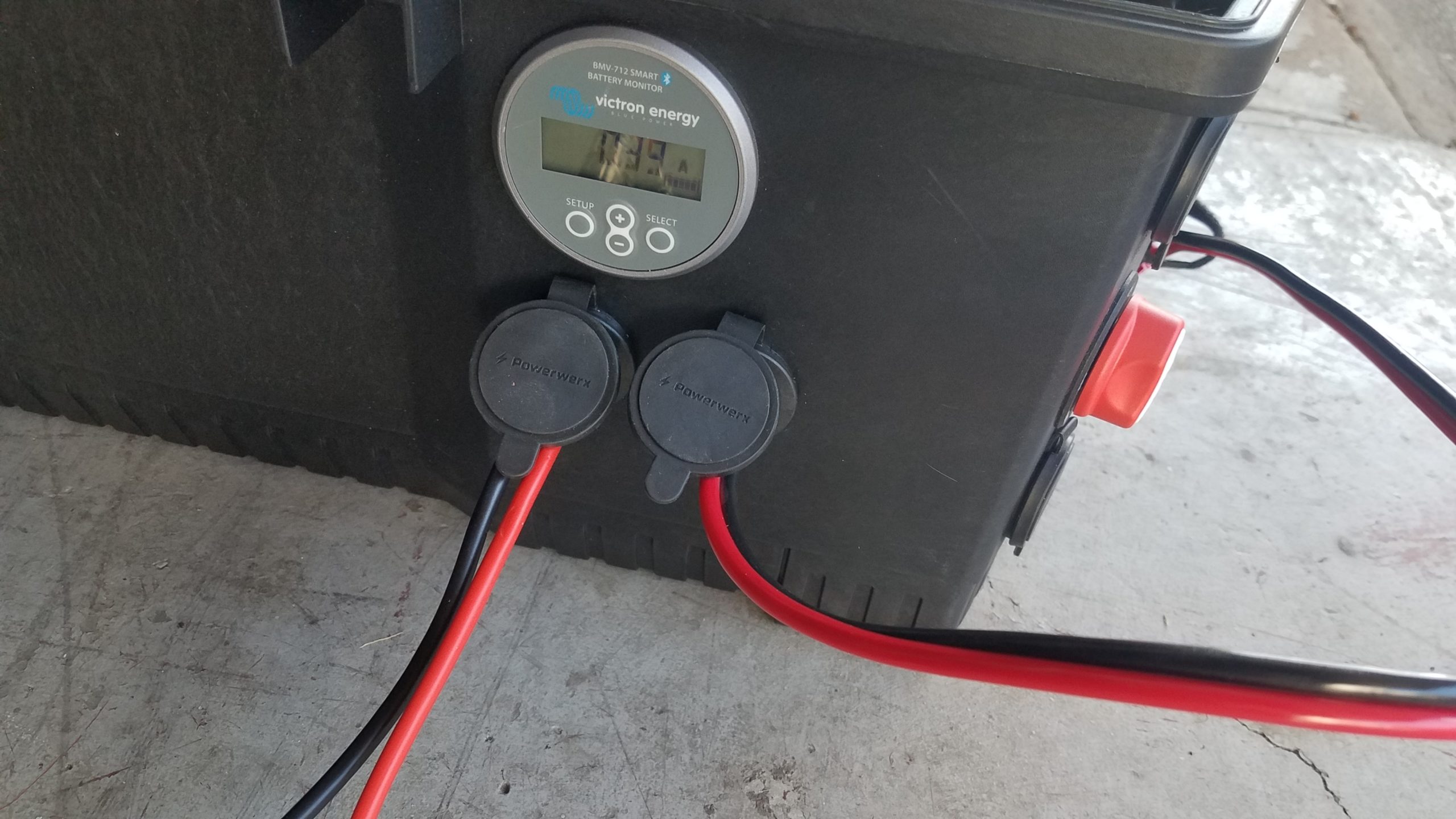

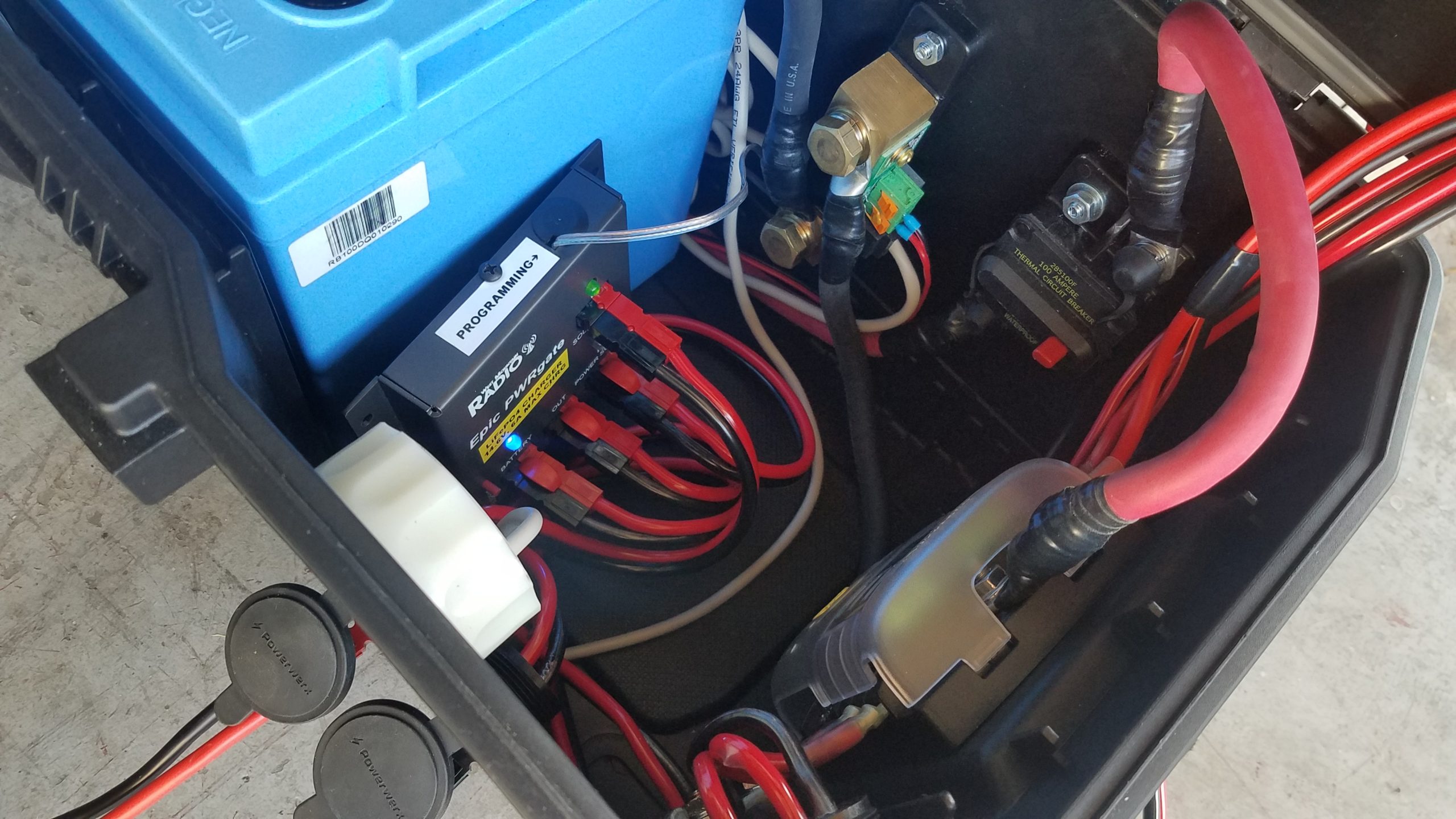

I added three new Powerpole ports to support the installation of a West Mountain Radio Epic PWRGate for use as a multisource battery charger and to allow one port on the battery box to function as a UPS, one as a DC charging input from a vehicle or other 12v power supply, and a solar panel input that can work with lower voltage (<30V) solar panels. I also added a charger disconnect switch that prevents the charger from acting as a parasitic load when it’s not in use. The specific disconnect switch I added allows the red rotary part of the swtich to be removed n the event you want to make sure the charger isn’t connected to the battery by mistake.

The Epic PWRGate connects to the ports with 10GA stranded copper wire to support 30 amp loads. The “battery” port on the PWRGate is connected to the battery via the DC disconnect switch and the DC subpanel. The leg of the circuit that connects the battery to the charger is also fused with a 30A fuse to allow it to operate a full power radio via the UPS port. The Epic PWRGate will charge a battery with a max current of 10A. I also added an optional temperature probe connected to the positive battery lug that will cut the charger off when the battery gets too cold or warm to prevent harm to the battery. The temperature parameters are configurable using the USB port. The appropriate USB cable, USB C, and USB A OTG cable adapters are included to connect a device with a serial terminal emulator installed.

This updated simplified build diagram for the 100Ah battery box includes the modifications that were being bench tested and will likely remain as a permanent addition to the system for charging from a vehicle or charging from a lower voltage (<30v) portable solar panel.

As a side note an added advantage of including a charger like the Epic PWRGate to this setup is that it can be re-configured to charge another battery, even of a different chemistry from the 100Ah LiFePO4 battery. You can charge a smaller battery or even charge a lead acid battery from it as well. This will require changing jumpers if you’re not programming the unit with a USB port, but I prefer programming it with a USB port as I get a better degree of control over the settings such as charge current than the onboard jumpers provide. It will also require swapping the battery and DC ports. The battery should be connected to the DC port and the DC port should be connected to the battery being charged. In the event the charger is re-configured I also include the custom LiFePO4 battery settings for my Relion RB100 that the kit is designed around so they can be restored on the charger without requiring memorization.

I also ended up having shading issues in the space that was available to set up the solar panels so I used the built-in eyelets and some paracord to suspend the panel in the sun to avoid shading on the ground. I was also able to slide the panel laterally on one piece of cord running left to right (east to west) near the water tank pictured. The other piece of paracord goes through both of the eyelets and forms a tiangle whose point is a knot and the single line of paracord runs back to a single anchor point from the triangle, and is pointed south. You can slide the panel side to side on the paracord running right to left (east to west) as the sun’s position in the sky changes. Getting the panel off the ground was extremely helpful because it got the system out of shadows cast accross the ground most of the day, and also required less maintenance as shadows tracked across the ground and threatened to partially or fully shade the solar panels. Instead the shadows were cast under the suspended panel.

The 100W folding panel was able to charge both a 19″ Macbook Pro connected to a 90W USB C car charger and a phone the an entire work day. This worked well on a bright day and on a cloudy day using this new configuration. I leverage MC4 connectors for the 100W panel to harden the connections against rain and dust. They’re adapted to Anderson Powerpole connectors for connection to the battery box using a pigtail I store in a zippered pouch on the back of the folding panel along with rolled lengths of wire with MC4 connectors attached.

This is an update to this post about building the battery box.